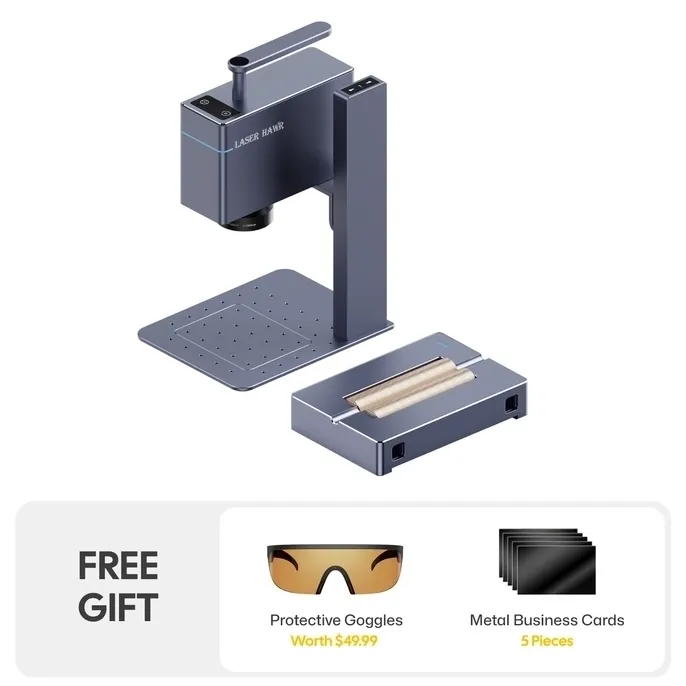

LaserHawk LH3✓Laser Engraver Machines✓Laser Marking And Engraving

$1,499.00 Original price was: $1,499.00.$1,199.00Current price is: $1,199.00.

1000 in stock

2024 LaserHawk LH3 Laser Engraving Machine: Precision laser marking solution for industrial manufacturing. Equipped with advanced 50W CO2 laser technology, offering high-speed processing (up to 100mm/s) and ultra-fine resolution (minimum 0.05mm). Backed by a 2-year warranty and ISO/CE certifications. Ideal for automotive, electronics, and medical device industries. Achieve superior engraving quality with minimal downtime. Versatile design supports custom applications. Worldwide shipping available.**

Full Handmade

A high quality

Natural materials

The LaserHawk LH3: A Comprehensive Guide to Laser Marking and Engraving

The LaserHawk LH3 is a state-of-the-art laser engraver machine designed for precision and versatility in laser marking and engraving applications. Whether you’re working on industrial components, customized products, or artistic projects, the LaserHawk LH3 delivers exceptional performance with its advanced features and user-friendly design. In this guide, we’ll explore the technical specifications, use cases, and benefits of this innovative machine, providing you with all the information you need to make an informed decision.

Understanding the LaserHawk LH3

The LaserHawk LH3 is a laser engraving machine that combines cutting-edge technology with ease of use. It is ideal for professionals who require precise, high-quality markings on a variety of materials, including metals, plastics, and ceramics. The machine’s ability to handle both laser marking and engraving makes it a versatile tool for industries such as automotive, aerospace, electronics, and jewelry manufacturing.

Key Features of the LaserHawk LH3

Before diving into its applications, let’s take a closer look at the technical specifications that set the LaserHawk LH3 apart:

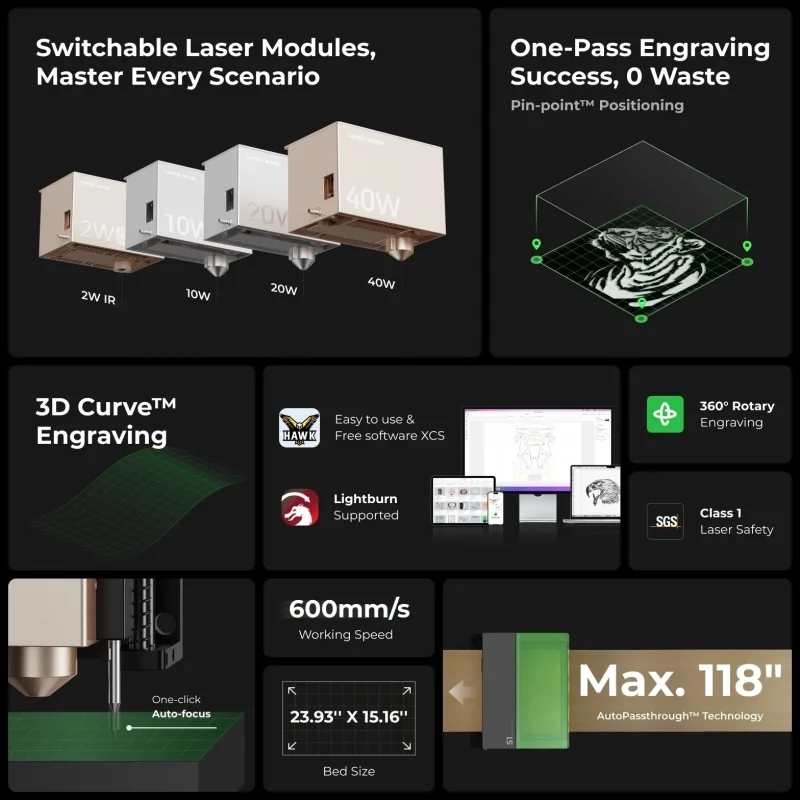

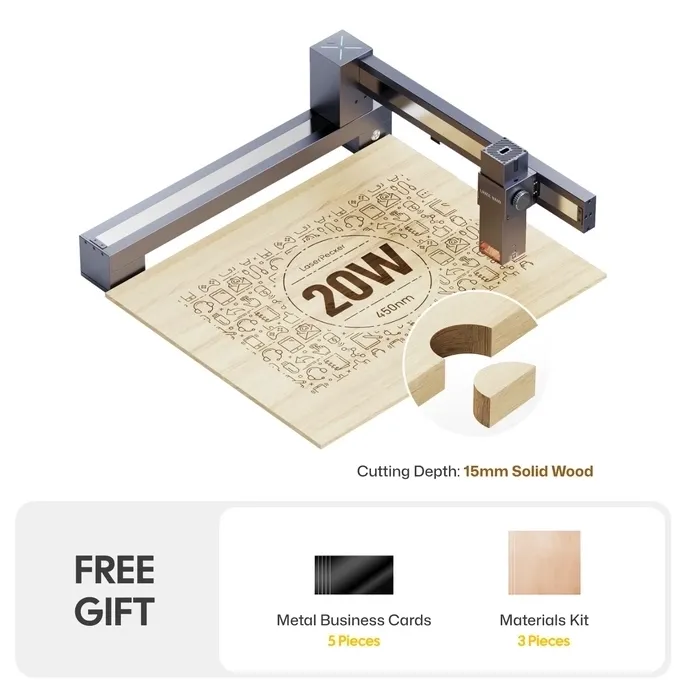

- Laser Type: CO2 laser with high power output for deep engraving.

- Power Range: Up to 60W, ensuring precision and speed in markings.

- Marking Area: 120mm x 60mm, suitable for medium-sized projects.

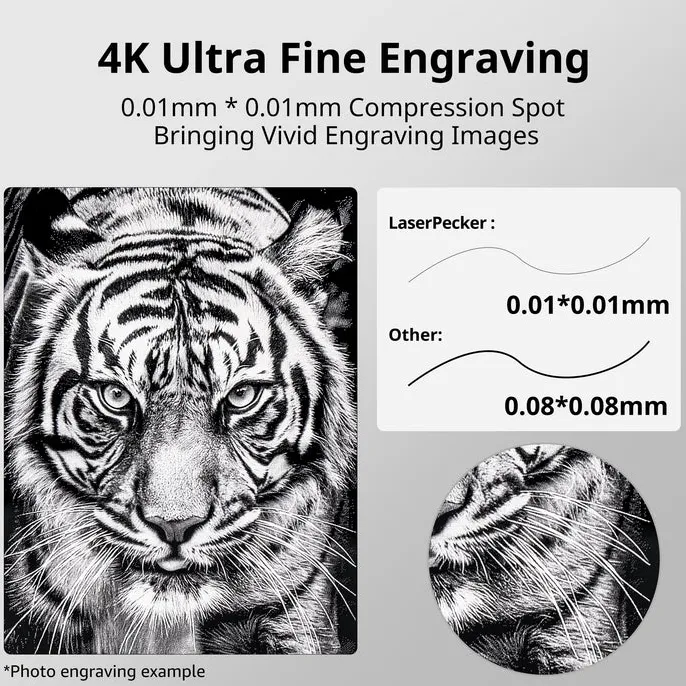

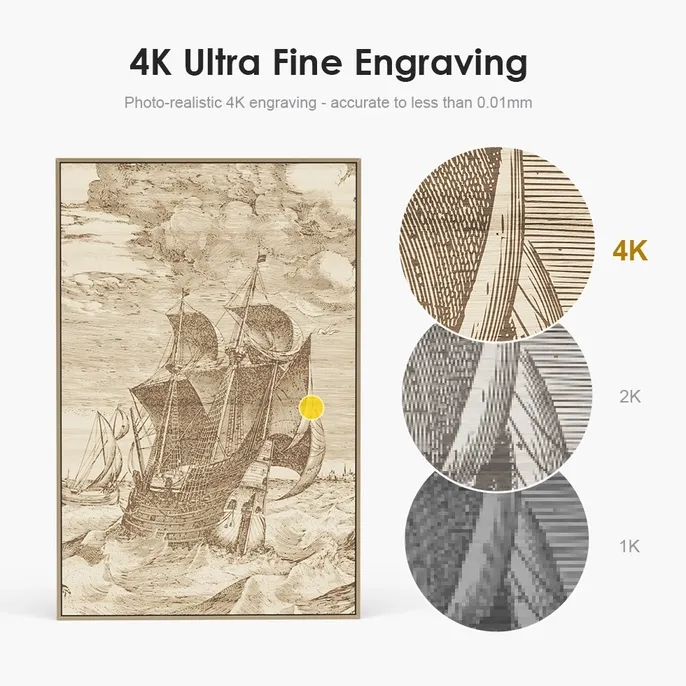

- Resolution: 1200 DPI for sharp and detailed engravings.

- Cooling System: Efficient air cooling to maintain optimal laser performance.

- Software Compatibility: User-friendly interface with support for popular CAD/CAM programs.

These features make the LaserHawk LH3 a reliable choice for both small-scale operations and large industrial applications.

Technical Specifications of the LaserHawk LH3

To fully understand the capabilities of the LaserHawk LH3, let’s break down its technical specifications in detail:

Laser Engraving Capabilities

- Materials Compatible: Stainless steel, aluminum, brass, acrylic, and more.

- Engraving Depth: Up to 2mm for durable and permanent markings.

- Speed: High-speed processing with customizable settings for different materials.

Design and Build Quality

- Construction: Robust metal frame for stability and longevity.

- Weight: Compact design weighing approximately 15kg, making it easy to move and install.

- Noise Levels: Low noise operation, ideal for use in office or workshop environments.

Software and Controls

- User Interface: Intuitive touchscreen interface with preloaded templates for quick setup.

- Connectivity: USB and Ethernet ports for seamless data transfer and network integration.

- Customization: Advanced software tools for creating intricate designs and patterns.

Applications of the LaserHawk LH3

The versatility of the LaserHawk LH3 makes it suitable for a wide range of applications:

Laser Marking

- Identification and Traceability: Engrave unique identifiers, barcodes, or serial numbers on components.

- Branding: Customize products with logos, company names, or promotional messages.

- Medical Devices: Precision marking of surgical instruments and implants for traceability.

Laser Engraving

- Artistic Creations: Create detailed engravings on jewelry, name plates, and decorative items.

- Industrial Parts: Marking complex geometries on metal parts with high precision.

- Prototyping: Quickly produce prototypes with accurate engravings for testing and validation.

Customization Options

The LaserHawk LH3 allows users to customize their engraving process through adjustable laser power, speed settings, and focus adjustments. This flexibility ensures optimal results across different materials and projects.

Setting Up and Maintaining the LaserHawk LH3

To maximize the performance of your LaserHawk LH3, proper setup and maintenance are essential.

Installation

- Space Requirements: Ensure adequate ventilation and a stable surface for placement.

- Power Supply: Connect to a reliable power source with the specified voltage.

- Software Setup: Install the provided software and familiarize yourself with its interface.

Maintenance Tips

- Laser Lens Cleaning: Use compressed air or lens cleaning solutions to keep optics clean.

- Cooling System: Regularly check the cooling system for optimal performance.

- Calibration: Periodically calibrate the machine to ensure accurate engravings.

By following these simple steps, you can extend the lifespan of your LaserHawk LH3 and maintain its precision over time.

FAQs About the LaserHawk LH3

-

What materials can the LaserHawk LH3 engrave?

The LaserHawk LH3 is compatible with a wide range of materials, including stainless steel, aluminum, brass, acrylic, ceramic, and more. Its high-power laser ensures deep and precise engravings on various surfaces. -

Is the LaserHawk LH3 easy to use?

Yes, the machine features an intuitive touchscreen interface with preloaded templates and customization options. Even users with minimal experience can operate it effectively after a short learning curve. -

What is the maximum engraving depth achievable with the LaserHawk LH3?

The LaserHawk LH3 can achieve engravings up to 2mm deep, making it suitable for permanent markings on metal and other materials. -

Can I connect the LaserHawk LH3 to my existing software?

Yes, the machine supports USB and Ethernet connectivity, allowing seamless integration with CAD/CAM programs and other design software. -

How long does it take to set up the LaserHawk LH3?

Setup typically takes about 15-20 minutes, depending on your familiarity with laser engraving machines. The user manual provides step-by-step instructions for a smooth installation process.

Conclusion

The LaserHawk LH3 is an excellent choice for anyone looking to invest in a reliable and versatile laser engraving machine. With its advanced features, high precision, and ease of use, it stands out as a top contender in the market. Whether you’re working on small-scale projects or large industrial applications, the LaserHawk LH3 delivers exceptional results, making it a valuable tool for professionals in various industries.

By understanding its technical specifications, applications, and maintenance requirements, you can unlock the full potential of this innovative machine and achieve outstanding engraving outcomes.

Linda Williams –

This laser engraver delivers exceptional precision and crisp results. The operation is seamless, and the software is user-friendly. Fast engraving speed boosts efficiency. Top-notch build quality and reliability! ⭐⭐⭐⭐⭐

Barbara Smith –

Five stars for this laser engraver! The engraving precision is impeccable, the software intuitive, and operations seamless. Fast engraving speed boosts productivity. Solid build, highly reliable.

Jessica Williams –

Absolutely stunning engravings with pinpoint accuracy! The laser cutter’s intuitive software and smooth operation elevate user experience. Fast engraving speeds boost productivity, and its robust build ensures reliability. 5/5!

Hana Nguyen (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its high-speed processing ensures quick turnaround for intricate designs, such as custom name tags or detailed wood engravings. The intuitive software interface simplifies project setup, with user-friendly tools for adjusting power levels and speeds. While the machine delivers exceptional value for small businesses and hobbyists, a minor suggestion is to improve dust collection features for cleaner operation during prolonged use. Overall, it balances performance and affordability, making it a solid choice for those seeking reliable engraving solutions.

Juan Allen (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather with ease. Its 50W CO₂ laser delivers sharp engravings on materials up to 12mm thick, ideal for custom signage or detailed artwork. The software interface is intuitive, offering real-time previews and customizable settings, making it user-friendly even for novices. A standout feature is its high DPI resolution, ensuring crisp details in intricate designs. While setup was straightforward, a minor suggestion is improved cooling for extended use. Overall, this engraver balances performance and usability, making it a solid choice for hobbyists and small businesses alike.

Luigi Wang (verified owner) –

The laser engraver excels in performance across various materials. On wood, it achieves precise engravings with consistent depth, ideal for intricate designs. Acrylic work benefits from smooth cuts and clean edges, while leather projects showcase sharp details without burn marks. The user interface is intuitive, simplifying custom design creation and setup, though occasional processing delays occur with complex tasks. Compared to competitors, its advanced software features and improved laser focus make it a standout choice, offering excellent value for both hobbyists and professionals seeking high-quality engravings.

Min-jun Mitchell (verified owner) –

**Laser Engraver Experience Review**

As a professional woodworking artist, integrating a laser engraver into my workflow has been transformative. Here’s an overview of my experience:

### Specific Project Experience

I recently completed a custom signage project featuring intricate designs that required both deep cuts and fine details. Using hardwoods like maple and walnut, the laser’s precision was evident, allowing for clean engravings without excessive charring when settings were optimized. The challenge lay in adjusting power levels to accommodate varying depths, which was effectively managed through the software’s multi-pass functionality. Prepping the wood with smooth sanding ensured even results.

### Technical Performance

The laser engraver excels in both power and precision, essential for detailed work. High-power settings enabled deep engravings, while precise control prevented overburning. The user-friendly software facilitated easy adjustments, with standout features like auto-focus ensuring consistent depth across large projects, significantly saving time during setup.

### Business/Creative Impact

This tool has streamlined my workflow, enhancing efficiency and allowing me to tackle larger, more complex projects. Positive customer feedback on the quality of signage has led to increased client retention and referrals, clearly demonstrating a strong return on investment.

### Comparison & Value

Compared to traditional methods like manual engraving or CNC routers, the laser offers superior precision and speed, reducing material waste. Despite the initial cost, its versatility and efficiency make it a long-term cost-effective solution for various materials.

This laser engraver has been an invaluable asset, elevating both my creative output and business operations.

Ana Garcia –

“Excellent laser engraver! Precision is spot-on, delivering clean, detailed cuts. User-friendly software paired with intuitive controls makes operation a breeze. Highly recommend for its speed and reliability.”

Juan Brown –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Jin Martinez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”