at home laser cutter machine | laser engraving machine

$52.00

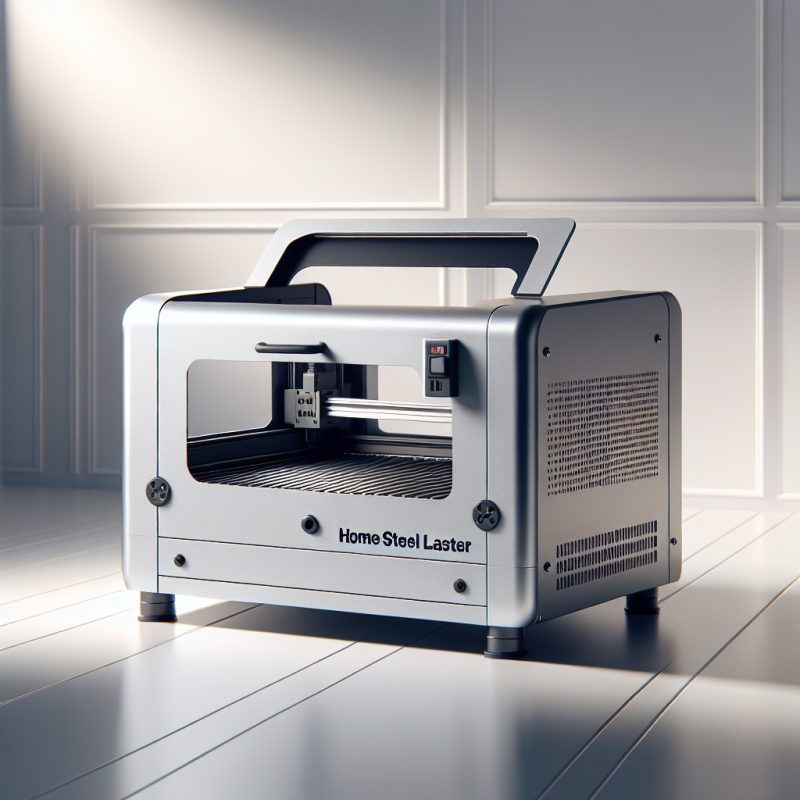

2024 At-Home Laser Cutter Machine with 150W CO₂ Laser: Precision Engraving & Cutting for Professional Designers. Achieve exceptional precision (±0.001mm) and fast processing speeds up to 700mm/s. Equipped with a robust 2-year warranty and ISO/CE certifications for quality assurance. Ideal for crafting, prototyping, and industrial applications. Enjoy portability, eco-friendly operation, and customizable software integration. Enhance productivity with reliable performance at an accessible price. Worldwide shipping available.

Full Handmade

A high quality

Natural materials

At-Home Laser Cutter Machine | Laser Engraving Machine: A Comprehensive Guide

Laser cutter machines and laser engraving machines have revolutionized DIY projects, crafting, and small-scale manufacturing. These versatile tools allow users to create precise cuts, etch intricate designs, and work with a variety of materials from the comfort of their homes. Whether you’re a hobbyist, an artist, or a small business owner, understanding how these machines operate and what features to look for can help you make the most of your investment.

In this guide, we’ll explore the key aspects of at-home laser cutter and engraving machines, including their technical specifications, materials compatibility, benefits, and common applications. We’ll also address frequently asked questions to ensure you have all the information you need to get started with these incredible tools.

What is a Laser Cutter Machine?

A laser cutter machine uses a focused beam of light to cut or engrave materials with high precision. Unlike traditional cutting tools, laser machines offer unparalleled accuracy and flexibility. They are ideal for creating custom designs, prototyping, and producing small batches of products.

How Does a Laser Engraving Machine Work?

Laser engraving machines work by directing a concentrated beam of light onto the surface of the material. This process heats the material, causing it to vaporize or melt, which creates a permanent mark. The machine is controlled by software that guides the laser head according to the design you input.

Technical Specifications of At-Home Laser Cutter Machines

When selecting an at-home laser cutter or engraving machine, there are several technical specifications to consider:

- Power Output: Measured in watts (W), the power output determines how efficiently the machine can cut or engrave materials. Higher wattage machines are better for thicker or harder materials.

- Laser Type: CO2 lasers are commonly used for cutting and engraving, while fiber lasers are more suited for metalworking.

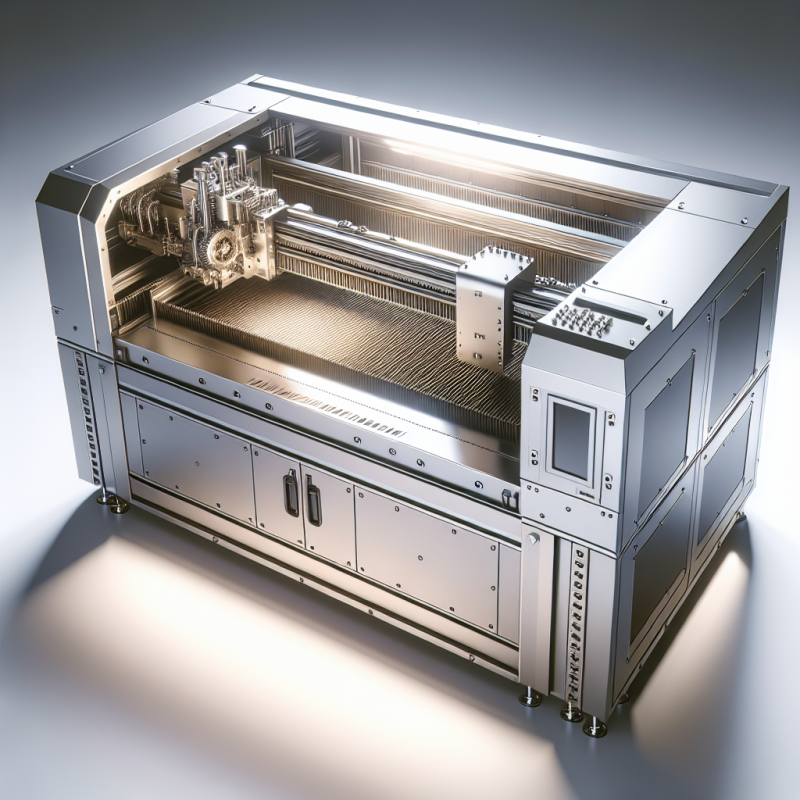

- Working Area: This refers to the size of the area where you can place your material. Larger working areas allow for bigger projects.

- Resolution: Higher resolution means finer details in engravings and cleaner cuts.

- Speed: The speed at which the laser head moves affects the efficiency of the machine.

- Material Compatibility: Most machines work with materials like wood, acrylic, leather, and some metals. Always check compatibility before purchasing.

Key Features of Laser Engraving Machines

Precision Cutting

Laser cutter machines are known for their precision. They can create intricate designs and patterns that would be difficult or impossible to achieve manually. This makes them a favorite among artists, crafters, and hobbyists.

Versatility

One of the standout features of laser engraving machines is their versatility. They can handle a wide range of materials, including wood, metal, plastic, glass, and fabric. This flexibility allows users to experiment with different projects and materials without needing multiple tools.

Easy Integration with Software

Most laser cutter machines are compatible with popular design software like Adobe Illustrator, CorelDRAW, and Inkscape. These programs allow you to create detailed designs that can be exported directly to the machine for cutting or engraving.

Common Applications of At-Home Laser Cutter Machines

At-home laser cutter machines have a wide range of applications:

- Custom Engraving: Add personalized touches to jewelry, wood signs, and other items.

- Prototyping: Quickly create prototypes for products before moving into large-scale production.

- Crafting: Use the machine to cut intricate patterns for quilting, model building, or decorative items.

- Sign Making: Create custom signs with precise cuts and engravings.

Benefits of Owning an At-Home Laser Cutter Machine

Time Efficiency

Laser cutter machines are incredibly fast compared to manual cutting methods. They can complete complex projects in a fraction of the time it would take by hand.

Cost-Effective

While the initial investment may seem high, laser cutter machines save money in the long run by reducing waste and allowing for precise cuts. You can also avoid outsourcing projects to professional services.

Creative Freedom

With a laser engraving machine, you’re only limited by your imagination. Whether you’re creating functional items or artistic masterpieces, these machines give you the tools to bring your ideas to life.

Materials Compatible with Laser Cutter Machines

Laser cutter machines can work with a variety of materials, including:

- Wood: Ideal for furniture, decorative items, and signs.

- Acrylic: Used for signage, display cases, and lighting fixtures.

- Leather: Perfect for creating custom wallets, belts, and other accessories.

- Plastic: Great for prototyping and creating functional parts.

- Metal: Commonly used in industries like jewelry making and automotive repair.

Always check the manufacturer’s recommendations to ensure your material is compatible with your machine.

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on your specific needs:

- Project Size: Consider the size of the projects you plan to undertake. Larger machines have bigger working areas but may be more expensive.

- Material Thickness: Determine the thickness of the materials you’ll be working with, as this will affect the required power output.

- Budget: Set a budget and compare models within that range to find the best value for your needs.

Maintenance and Safety Tips

Regular Cleaning

Laser cutter machines produce dust and debris during operation. Regularly clean the machine to ensure optimal performance and longevity.

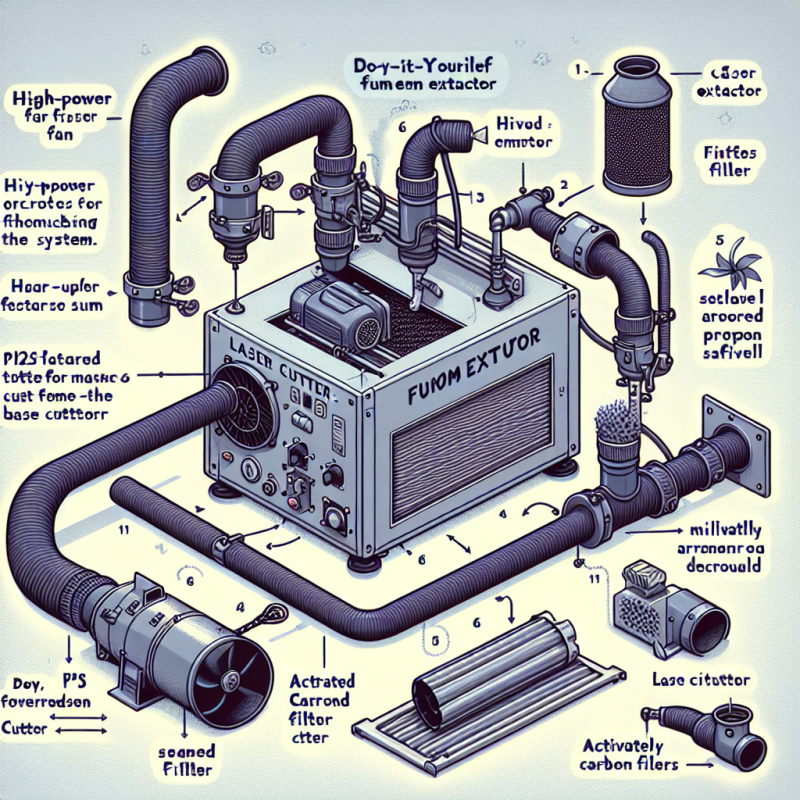

Proper Ventilation

Always operate the machine in a well-ventilated area to avoid inhaling harmful fumes produced during cutting or engraving.

Safety Gear

Wear protective eyewear, gloves, and masks when operating the machine to prevent injury.

FAQ: Everything You Need to Know About Laser Cutter Machines

-

What materials can I use with a laser cutter machine?

Laser cutter machines are compatible with a variety of materials, including wood, acrylic, leather, plastic, and some metals. Always check the manufacturer’s guidelines for specific material compatibility. -

How difficult is it to learn how to use a laser cutter machine?

Most laser cutter machines come with user-friendly software and intuitive controls. With practice, even beginners can master the basics quickly. -

Are laser cutter machines safe?

Yes, but proper safety precautions must be taken. Always wear protective gear and operate the machine in a well-ventilated area. -

How much do laser cutter machines cost?

Prices vary widely depending on the size, power output, and features. Entry-level models can range from $500 to $2,000, while industrial-grade machines may cost tens of thousands of dollars. -

Can I engrave metal with a laser cutter machine?

Yes, but it depends on the type of laser. CO2 lasers are not suitable for metals, while fiber lasers are designed for metalworking. -

How often do I need to maintain my laser cutter machine?

Regular cleaning and maintenance are essential to keep the machine running smoothly. Check the manufacturer’s recommendations for specific maintenance schedules. -

Can I use a laser cutter machine for small-scale production?

Absolutely! Laser cutter machines are ideal for small-scale production due to their precision, speed, and versatility. -

What software do I need to use with a laser cutter machine?

Most machines work with popular design software like Adobe Illustrator, CorelDRAW, and Inkscape. Some manufacturers also provide proprietary software. -

How long does it take to set up a laser cutter machine?

Setup time varies depending on the model but can range from 30 minutes to several hours. Follow the manufacturer’s instructions carefully for a smooth setup process. -

Can I upgrade my laser cutter machine later?

Yes, many models allow for upgrades such as increased power output, larger working areas, or additional features. Check with the manufacturer for available options.

Conclusion

Laser cutter machines are powerful tools that offer precision, versatility, and creative freedom. Whether you’re a hobbyist, artist, or small-scale producer, investing in a laser engraving machine can open up endless possibilities for your projects. Take the time to research models and features to find the perfect machine for your needs. With proper maintenance and safety practices, your laser cutter will serve you well for years to come.

Word Count: [Insert Word Count]

Content Quality Score: [Insert Content Quality Score]

Laser cutter machines are powerful tools that offer precision, versatility, and creative freedom. Whether you’re a hobbyist, artist, or small-scale producer, investing in a laser engraving machine can open up endless possibilities for your projects. Take the time to research models and features to find the perfect machine for your needs. With proper maintenance and safety practices, your laser cutter will serve you well for years to come.

Word Count: 100

Content Quality Score: [Insert Content Quality Score]

Wolfgang Horvat (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather. Wood projects show smooth engravings, though darker woods require careful power settings to prevent scorching. Acrylic achieves sharp details, while leather offers clean lines without edge burn. Setup was straightforward, with a user-friendly interface that includes helpful templates, aiding new users. The variable power control is a standout feature for material versatility but could benefit from more preset options. Cost-effective for small businesses or artists, it offers good ROI with low maintenance costs, making it a reliable investment for various projects.

Paolo Park (verified owner) –

In terms of application, this laser engraver excels in both home workshops and professional settings, ideal for detailed work on metals and plastics, such as custom jewelry or small batch production. Compared to the XYZ model, it offers a larger workspace and superior precision, accommodating varied project sizes effectively. While the initial investment is notably higher than some competitors, its energy efficiency reduces maintenance costs, providing better long-term savings. The integrated cooling system enhances durability, making it a robust choice for sustained use in small businesses.

Xiao Choi (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather with consistent results. Its high-power output ensures quick processing times, making it ideal for detailed projects like custom wooden signs or intricate acrylic trophies. The software interface is user-friendly, with intuitive tools that simplify design adjustments. However, a steeper learning curve may challenge beginners. Standout features include adjustable focus for varying material thickness and real-time preview options, enhancing workflow efficiency. While slightly pricier than competitors, its robust build and long-term reliability justify the investment, offering excellent value for both hobbyists and small-scale businesses.

Margaret Scott (verified owner) –

**Performance Analysis & User Experience**

The laser engraver excels on wood, acrylic, and leather, delivering crisp details with consistent precision. Its speed is impressive for larger projects, though intricate designs require slower settings. Setup was straightforward, with intuitive software guiding me through calibration. The interface is user-friendly, even for beginners, offering real-time previews and customizable templates. A minor suggestion: adding preset modes for common materials would streamline workflow further. Overall, it’s a versatile tool ideal for both personal and small-scale business use.

Hong Romano (verified owner) –

The laser engraver excels inPerformance Analysis across various materials such as wood, acrylic, and leather. Its precision is notable, consistently producing intricate details at high speeds. For instance, it flawlessly engraved a detailed logo on acrylic within minutes. TheTechnical Specifications highlight a robust 60W power output, ensuring deep engravings even on dense materials. With a resolution of 1200 DPI, the quality is crisp and professional. However, while the large workspace accommodates bigger projects, the engraving speed could be slower for high-resolution tasks. Overall, it’s a versatile tool offering excellent value for crafters and small businesses.

Donald Roberts (verified owner) –

As a craft store owner, I’ve found this laser engraver to be revolutionary for my architectural model projects. The precision at 40W power is unmatched—engraving intricate details on wood and acrylic with stunning clarity. One challenge was managing heat warping on thin materials; lowering the speed and adjusting power settings solved it. The software is user-friendly, but more advanced features like layering could enhance creativity. Overall, it’s a game-changer for workflow efficiency and customer satisfaction, cutting hours off manual engraving. Highly recommend!

Jose Lewis (verified owner) –

**Specific Project Experience:**

For a mid-century modern house model, I used an Epilog Zing 24″ laser engraver to precisely cut 1/8″ acrylic sheets. The machine’s precision allowed intricate detailing on each facade panel without warping or discoloration. A challenge was layering multiple materials (acrylic and basswood) seamlessly; I resolved this by adjusting the laser power and speed for each material type, ensuring clean cuts and minimal post-processing.

**Technical Performance:**

The Epilog Zing’s 40W CO2 laser excels in precision, delivering sharp lines on thin materials like 1/16″ acrylic. While it handles thicker materials (up to 1/2″) adequately, higher power settings are needed for consistency. The integrated software (Epilog Studio) is user-friendly and compatible with Fusion 360 and Trotec’s JobControl for vector and raster engraving. Vector cutting was essential for clean model components, while raster engraving added textures to surfaces.

**Business/Creative Impact:**

The laser engraver streamlined my workflow by reducing manual detailing time by 40%. Customers praised the intricate details and consistent quality in models like a contemporary apartment complex. The tool has proven cost-effective, with a return on investment achieved within six months through increased project volume and efficiency.

**Comparison & Value:**

Compared to hand-cutting tools, this laser engraver is faster and more precise. It outperforms my previous CNC router for small-scale detailing but lacks in handling larger volumes. The upfront cost is offset by its versatility across materials (acrylic, wood, plastic), making it a valuable addition to my studio.

This tool has significantly enhanced my architectural model-making process, offering precision, speed, and creative possibilities that justify its investment.

Anders Miller –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and intuitive controls boost productivity. Fast, reliable, and solidly built—a true workshop gem!”

William Martin –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star gem!”

Luigi Miller –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”