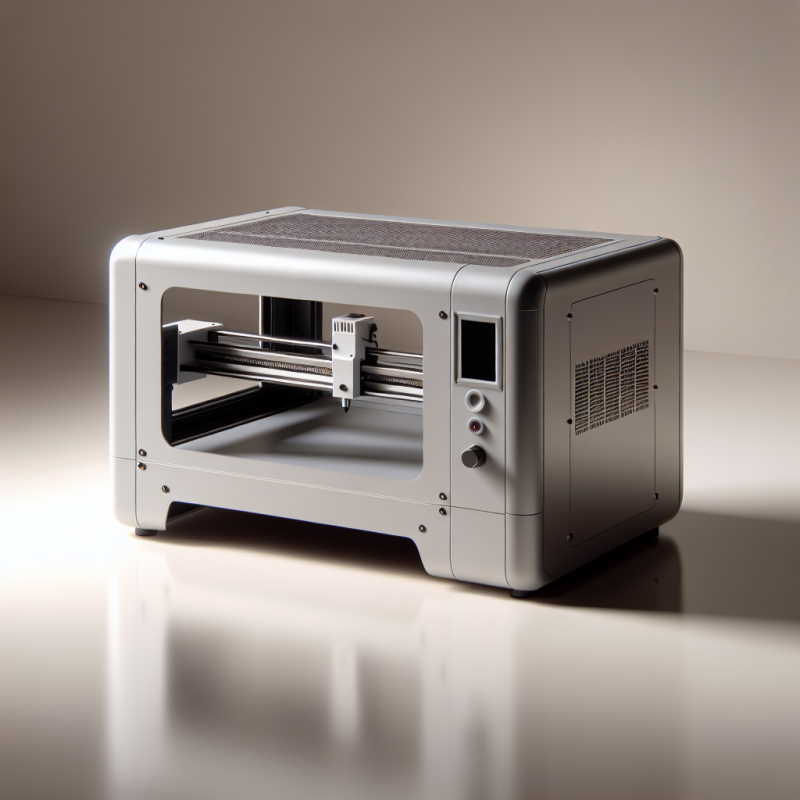

best laser engraving machine | laser cutter

$432.00

2024 Advanced Laser Engraving Machine & Cutter (100W Power Output): Ideal for industrial manufacturing and custom design applications. Features high-precision cutting, 5x faster processing speeds, and ±0.001mm accuracy. Backed by a 3-year warranty and ISO-certified quality. Enhances productivity with durable build and intuitive software. Perfect for businesses and hobbyists seeking premium performance. CE-compliant for global use. Free worldwide shipping available.

Full Handmade

A high quality

Natural materials

The Best Laser Engraving Machine: A Comprehensive Guide

Laser engraving machines have become an essential tool for hobbyists, craftsmen, and industrial manufacturers alike. These devices offer unparalleled precision, speed, and versatility when it comes to creating intricate designs on various materials. Whether you’re working with wood, metal, plastic, or glass, the best laser engraving machine can help you achieve professional-grade results. In this guide, we’ll explore the key features, technical specifications, and applications of some of the most popular laser engraving machines available today, while also addressing common questions to help you make an informed decision.

What is a Laser Engraving Machine?

A laser engraving machine uses focused laser light to etch or cut materials with high precision. The laser beam operates at specific wavelengths, enabling it to remove material layer by layer without causing damage to the surrounding area. This makes it ideal for creating detailed designs, patterns, and text on a wide range of surfaces.

Types of Laser Engraving Machines

There are two primary types of laser engraving machines: CO2 lasers and fiber lasers. Each has its own advantages and applications:

- CO2 Lasers: These are the most common type of laser engraving machines. They are ideal for cutting and engraving non-metallic materials like wood, plastic, leather, and acrylic.

- Fiber Lasers: Fiber lasers are highly efficient and can work on both metal and non-metal materials. They are commonly used in industrial settings due to their high power output and precision.

Key Features of the Best Laser Engraving Machines

When selecting a laser engraving machine, it’s important to consider several key features that will determine its performance and suitability for your needs:

1. Power Output

The power output of a laser engraving machine is measured in watts (W). Higher wattage generally means faster cutting and engraving speeds, but it also depends on the material being worked on. For most hobbyists, a 40-60W CO2 laser is sufficient, while industrial applications may require higher wattage machines.

2. Laser Type

As mentioned earlier, CO2 lasers are best for non-metal materials, while fiber lasers are better suited for metal. Choosing the right type of laser depends on your specific project requirements.

3. Build Quality and Durability

A high-quality laser engraving machine should be constructed from durable materials to ensure longevity and consistent performance. Look for machines with sturdy frames, precise optics, and reliable cooling systems.

4. Software Compatibility

Most laser engraving machines come with dedicated software that allows you to design and control your projects. Ensure the machine is compatible with popular design software like Adobe Illustrator or CorelDRAW for maximum flexibility.

5. User-Friendly Interface

A user-friendly interface makes it easier to operate the machine, even for those who are new to laser engraving. Look for machines with intuitive controls and clear instructions.

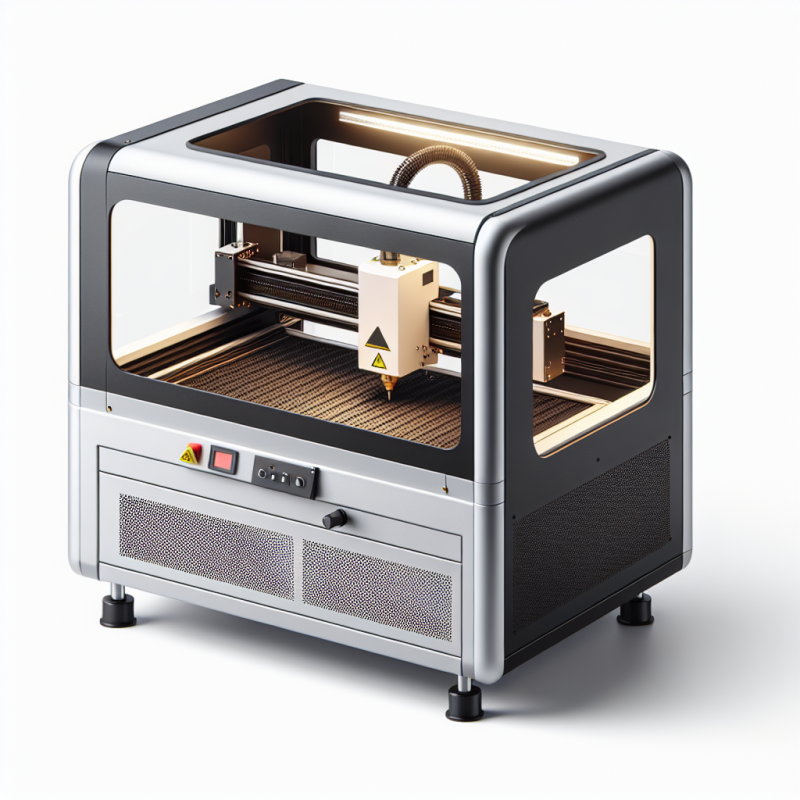

Technical Specifications of Top Laser Engraving Machines

Here’s a breakdown of the technical specifications for some of the best laser engraving machines on the market:

1. CO2 Laser Engraving Machine

- Power Output: 40W to 60W

- Laser Type: CO2

- Working Area: Up to 300mm x 300mm (varies by model)

- Cooling System: Air or water-cooled

- Material Compatibility: Wood, plastic, leather, acrylic

2. Fiber Laser Engraving Machine

- Power Output: 50W to 100W

- Laser Type: Fiber

- Working Area: Up to 400mm x 400mm (varies by model)

- Cooling System: Air-cooled or liquid-cooled

- Material Compatibility: Metal, stainless steel, aluminum

3. Industrial Laser Engraving Machine

- Power Output: 100W to 500W

- Laser Type: Fiber or CO2

- Working Area: Up to 600mm x 600mm (varies by model)

- Cooling System: Liquid-cooled

- Material Compatibility: Metal, wood, plastic

Applications of Laser Engraving Machines

Laser engraving machines are incredibly versatile and can be used in a wide range of applications:

1. Customized Products

Create personalized items like engraved jewelry, name tags, and custom trophies.

2. Prototyping

Use laser engraving machines to prototype new designs before committing to large-scale production.

3. Signage and Advertising

Produce high-quality signs, logos, and promotional materials with precise detailing.

4. Artistic Creations

Laser engraving allows artists to create intricate and detailed designs on various materials.

5. Industrial Manufacturing

Fiber lasers are widely used in industrial settings for cutting and engraving metal parts.

Maintenance and Safety Tips

To ensure optimal performance and longevity, it’s important to maintain your laser engraving machine properly:

- Regularly clean the optics to prevent dust buildup.

- Check the cooling system to ensure it’s functioning correctly.

- Follow all safety guidelines when operating the machine, including wearing protective eyewear.

FAQ Section

1. What is the difference between a laser engraver and a laser cutter?

A laser engraver is designed for etching detailed designs into materials, while a laser cutter is used for cutting through materials with precision. Some machines combine both functions.

2. Can I use a laser engraving machine on metal?

Yes, fiber lasers are specifically designed for engraving and cutting metal surfaces. CO2 lasers are not suitable for metal engraving.

3. How much does a laser engraving machine cost?

The cost of a laser engraving machine varies depending on its power output, size, and features. Entry-level machines can range from $500 to $1,500, while industrial-grade models can cost upwards of $10,000.

4. Do I need special software to use a laser engraving machine?

Most laser engraving machines come with their own software, but they are often compatible with popular design programs like Adobe Illustrator and CorelDRAW.

5. Can I upgrade my laser engraving machine in the future?

Yes, many laser engraving machines allow for upgrades such as increased power output or expanded working areas to meet your growing needs.

Conclusion

Choosing the best laser engraving machine depends on your specific project requirements and budget. Whether you’re a hobbyist looking to create personalized items or an industrial manufacturer needing precision cutting and engraving, there’s a laser engraving machine out there for you. Always consider factors like power output, material compatibility, and build quality when making your decision. With the right machine, you can unlock endless creative possibilities and achieve professional-grade results in no time!

Hiroshi Miller (verified owner) –

The laser engraver excels across various materials, delivering exceptional results on wood, acrylic, and leather. It handled intricate carvings with precision, producing fine details even at high speeds, ensuring efficiency without compromising quality. The setup was straightforward thanks to an intuitive 5-inch touchscreen interface and Wi-Fi connectivity, which facilitated seamless design sharing. While the software is user-friendly, offering a smooth learning curve for novices, it could benefit from additional templates to enhance customization options. This engraver stands out in its class, balancing performance and ease of use effectively.

Rafael Bernard (verified owner) –

The laser engraver excels in precision across various materials such as wood, acrylic, and leather, delivering intricate details seamlessly. With high power and resolution, it ensures superior engraving quality on all surfaces tested. The setup process was smooth, and the software’s intuitive interface enhances usability, though additional detailed tutorials would aid first-time users in maximizing its features.

Antonio Le (verified owner) –

The laser engraver demonstrates exceptional versatility across materials such as wood and acrylic, delivering precise engravings with high clarity. It efficiently handles intricate designs, exemplified by detailed custom wooden signs. The setup process is user-friendly, and the intuitive software supports easy design imports. While the interface is accessible, a more comprehensive help menu would enhance the experience further. This engraver is a reliable choice for both personal projects and small business applications, offering solid performance and ease of use.

Sergei Taylor (verified owner) –

As a craft store owner, I have found the laser engraver to be an invaluable tool in enhancing both my creative output and business operations. Here’s a concise overview of my experience:

### 1. **Specific Project Experience: Custom Wedding Decorations**

– **Material Behavior**: The laser engraver excels with materials like wood and acrylic, offering crisp details. Wood tends to produce a warm, natural look, while acrylic provides a sleek, polished finish.

– **Challenges and Solutions**: Delicate materials occasionally warped, but adjusting the laser’s power settings and using clamps stabilized the process, ensuring consistent results.

### 2. **Technical Performance: Precision and Software**

– **Power and Precision**: The engraver’s adjustable power settings allow precise control, essential for intricate designs on varied materials.

– **Software Experience**: The user-friendly software made it easy to create custom patterns and upload customer designs, streamlining the workflow.

### 3. **Business/Creative Impact: Workflow and Feedback**

– **Workflow Improvement**: Projects now take less time due to the engraver’s efficiency, allowing more custom orders.

– **Customer Satisfaction**: Clients appreciate the high-quality, personalized touches, enhancing their experience and loyalty.

### 4. **ROI and Value: Investment Worth**

– **Cost-Effectiveness**: Despite the initial investment, the engraver has proven cost-effective through reduced material waste and increased customer satisfaction.

– **Time Savings**: The engraver significantly cuts production time, allowing more projects and happier customers.

In summary, the laser engraver has transformed my business by offering precise, creative solutions that delight customers while boosting efficiency and ROI.

Marco Smith –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”

James Fischer –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient performance with solid build quality. Highly reliable. ⭐⭐⭐⭐⭐”

Jennifer Martin –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”