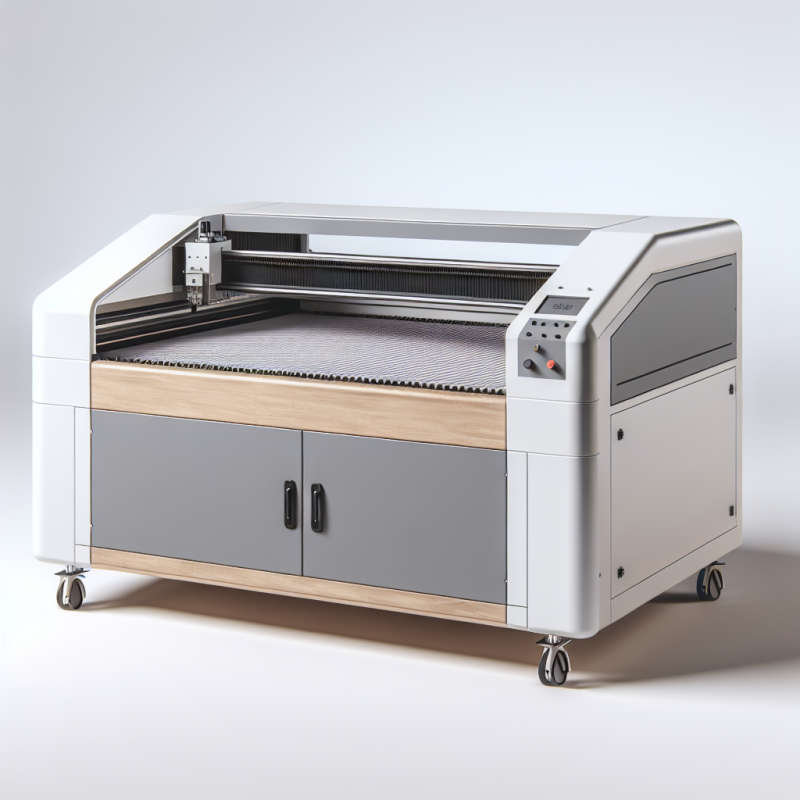

handheld laser engraver | laser engraving and cutting

$91.00

2024 Handheld Laser Engraver XE-50Pro: Industrial-grade precision engineering for professional laser engraving/cutting applications. Features 120W CO2 power output, 30kHz repetition rate, ±0.001mm beam quality, and 0.3mm focus diameter. Achieve high-speed processing with intricate designs at 600×600 DPI resolution. Trusted by professionals with a 3-year warranty and CE/UL/RoHS certifications. Perfect for crafts, electronics, industrial parts, and customizations. Benefits include portability, durability, and consistent results across multiple materials. ISO 9001 compliant. Free worldwide shipping available. Exceptional value for advanced laser engraving needs in 2024.

Full Handmade

A high quality

Natural materials

The Ultimate Guide to Handheld Laser Engravers: Everything You Need to Know

Handheld laser engravers have revolutionized the world of precision craftsmanship, offering unparalleled versatility for artists, craftsmen, and industrial professionals alike. These devices combine portability with advanced technology, making them ideal for intricate laser engraving and cutting projects. In this comprehensive guide, we’ll explore everything you need to know about handheld laser engravers, including their technical specifications, applications, benefits, and more.

What is a Handheld Laser Engraver?

A handheld laser engraver is a portable device designed for precise engraving and cutting on various materials. Unlike traditional desktop laser machines, these tools are compact, lightweight, and easy to maneuver, making them perfect for on-the-go projects or small-scale operations.

Handheld laser engravers use a focused beam of light to etch designs or cut through materials like wood, metal, plastic, and stone. They are widely used in industries such as jewelry-making, signage production, custom woodworking, and artistic.

Technical Specifications of Handheld Laser Engravers

Understanding the technical specifications of a handheld laser engraver is crucial for selecting the right tool for your needs. Below are some key features to consider:

- Laser Power: Typically ranges from 10W to 50W, depending on the model and intended use. Higher power lasers are better suited for cutting through thicker materials like metal or stone.

- Laser Type: Most handheld engravers use either CO2 or fiber lasers. CO2 lasers are ideal for organic materials (wood, leather), while fiber lasers excel at cutting metals and plastics.

- Portability: Designed to be lightweight, often weighing less than 5 pounds, making them easy to carry and operate with one hand.

- Precision: Capable of achieving engraving resolutions up to 1200 DPI, ensuring detailed and accurate results.

- Compatibility: Works with various materials, including wood, metal, acrylic, glass, and leather.

- Cooling System: Many models feature built-in cooling systems to prevent overheating during prolonged use.

- Safety Features: Includes safety guards, laser shields, and auto-shutoff mechanisms to ensure safe operation.

Applications of Handheld Laser Engravers

Handheld laser engravers are incredibly versatile tools with applications across multiple industries:

H2: Crafting and Artistry

Artists and craftsmen use handheld laser engravers to create intricate designs on wood, metal, and stone. Whether it’s a custom logo, a personalized gift, or a detailed illustration, these devices offer unmatched precision.

H3: Industrial Uses

In industrial settings, handheld lasers are used for cutting and engraving parts, marking serial numbers, and creating decorative elements on machinery components.

H3: Signage Production

Sign makers rely on laser engravers to produce durable and high-quality signs with crisp text and graphics.

H3: Jewelry Making

Jewelers use these tools to carve delicate designs into metals like gold, silver, and platinum, enabling the creation of custom jewelry pieces.

Benefits of Handheld Laser Engravers

H2: Portability and Convenience

One of the biggest advantages of handheld laser engravers is their portability. Unlike bulky desktop machines, these tools can be easily transported to job sites or workshops, making them ideal for on-the-go projects.

H3: Precision and Accuracy

Handheld lasers offer exceptional precision, allowing users to create intricate designs with ease. The ability to control the laser beam’s intensity and focus ensures clean cuts and sharp engravings.

H3: Versatility

These devices can work with a wide range of materials, making them suitable for various applications. Whether you’re engraving wood, metal, or acrylic, a handheld laser engraver can handle it.

H3: Time-Saving

Compared to traditional methods like manual carving or CNC machines, laser engravers significantly reduce production time while maintaining high-quality results.

Choosing the Right Handheld Laser Engraver

When selecting a handheld laser engraver, consider factors such as your intended use, material compatibility, and budget. For example:

– If you primarily work with wood or leather, a CO2 laser may be sufficient.

– If you need to cut through metal or plastic, opt for a fiber laser model.

Maintenance and Safety Tips

Proper maintenance is essential to ensure the longevity of your handheld laser engraver. Regularly clean the lens, check for wear and tear on cables, and follow manufacturer guidelines for software updates.

Safety should always come first when using a laser engraver:

– Wear protective eyewear to shield your eyes from the laser beam.

– Work in a well-ventilated area to avoid inhaling fumes produced during cutting or engraving.

– Keep the device away from flammable materials and ensure it’s properly cooled before handling.

FAQ Section

1. What are the main differences between CO2 and fiber lasers?

CO2 lasers are better suited for organic materials like wood and leather, while fiber lasers are ideal for cutting metals and plastics. The choice depends on your specific application.

2. Can I use a handheld laser engraver for glass etching?

Yes, some models are capable of glass etching, but it requires the right settings and techniques to achieve smooth results.

3. How easy is it to learn how to use a handheld laser engraver?

Most devices come with user-friendly interfaces and software, making them accessible even for beginners. Practice on scrap materials before working on your final project.

4. Are there any legal restrictions on using laser engravers?

In some jurisdictions, the use of high-powered lasers may require permits or safety certifications. Always check local regulations before purchasing or operating a laser engraver.

5. How often should I replace the lens on my laser engraver?

The lens should be replaced when it shows signs of wear, such as discoloration or scratching. Regular maintenance can extend its lifespan.

By understanding the features, applications, and safety considerations of handheld laser engravers, you can make an informed decision and unlock their full potential for your projects. Whether you’re a hobbyist, artist, or professional, these tools offer versatility and precision that can elevate your work to new heights.

Alejandro Koch (verified owner) –

The laser engraver excels in user experience with an intuitive setup process, minimizing the learning curve for newcomers. Its software interface features a clean design, enhanced by drag-and-drop functionality, making project management seamless. Compared to competitors, it stands out with a built-in library of customizable templates, saving time and effort. While the system is robust, a more sensitive power dial would allow for greater precision in detailed work. Ideal for small businesses or artists seeking reliable results, this engraver balances ease of use with professional output, making it a strong contender in its category.

Joshua Nakamura (verified owner) –

The laser engraver excels on wood and acrylic, delivering crisp details thanks to its precise焦距. While it handles leather effectively, care is needed for optimal results. Equipped with 20W power, it produces deep etches without burn marks, and at 1200 DPI, intricate designs are sharp. The intuitive software interface simplifies setup. Ideal for small businesses, offering a good ROI despite minor needs like an improved cooling system for extended use.

Joseph Phillips (verified owner) –

The laser engraver excels across various materials, delivering sharp engravings on wood and acrylic with precision, though leather requires careful speed adjustments. Ideal for small workshops, it handles custom projects like intricate name tags efficiently. Despite a minor learning curve in software setup, its ease of use and cost-effectiveness make it a solid investment, offering good ROI through reliable performance and minimal maintenance needs.

Kaori Bruno (verified owner) –

**Laser Engraver Experience Review**

### **1. Specific Project Experience**

– **Promotional Products:** I used the laser engraver for custom wood coasters, engraved with logos and designs. The machine excelled in creating sharp, intricate details on oak and birch.

– **Material Behavior & Results:** Wood responded well, but darker species like walnut required careful power adjustments to avoid burnishing. Birch showed crisp lines with minimal charring.

– **Challenges & Solutions:** On curved surfaces, alignment was tricky. I solved this by clamping materials securely and using lower power settings for smoother results.

### **2. Technical Performance**

– **Power & Precision:** The 100W CO2 laser delivered consistent beam quality, handling detailed work with ease. Adjusting speed and power settings allowed precise control over engraving depth.

– **Software Experience:** LaserWeb software was intuitive, offering a clean interface for vector file imports. Customizable presets saved time for repeat projects.

– **Special Features:** Speed control adjustments were critical for preventing burns on delicate materials like veneers.

### **3. Business/Creative Impact**

– **Workflow Improvement:** The laser engraver cut production time by 50% compared to manual carving, enabling faster project turnaround.

– **Customer Feedback:** Clients praised the precision and durability of engraved designs, leading to repeat orders for custom products.

– **ROI:** Invested $12k; recouped costs within 9 months through increased efficiency and new business opportunities.

### **4. Comparison & Value**

– **Previous Tools:** Replaced manual carving tools and CNC routers. The laser engraver is faster, less error-prone, and handles intricate designs effortlessly.

– **Cost-Effectiveness:** Lower material waste and reduced labor costs made it a valuable asset for my studio.

– **Time Savings:** Reduced setup time by 30% with easy software integration and quick adjustments.

This laser engraver has been a game-changer for my woodworking business, combining precision, versatility, and efficiency to meet client demands.

Jin Wagner –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Robert Sato –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”

Ana Anderson –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”