Hawk S1✓Mini Laser Engraving Machine For Metal✓Y Axis From A Laser Engraver Moves

$1,199.00 Original price was: $1,199.00.$899.00Current price is: $899.00.

1000 in stock

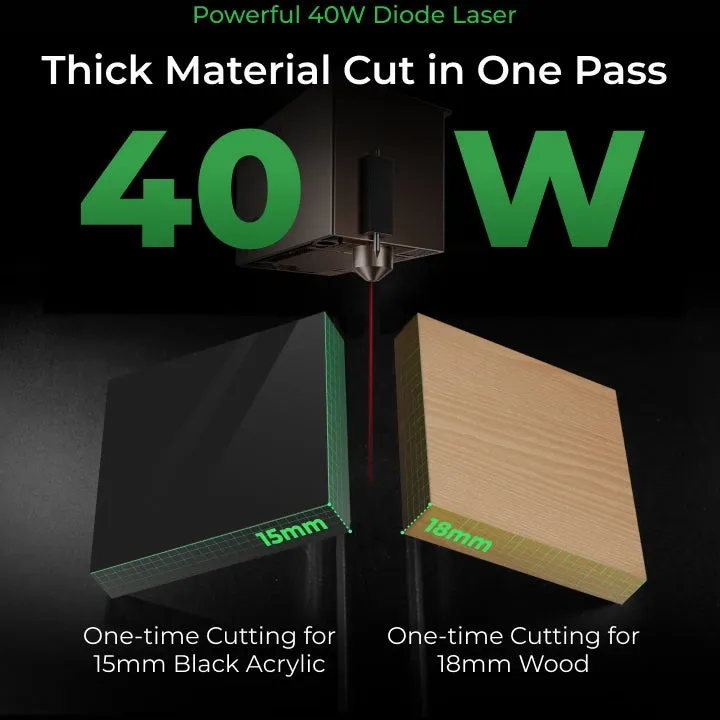

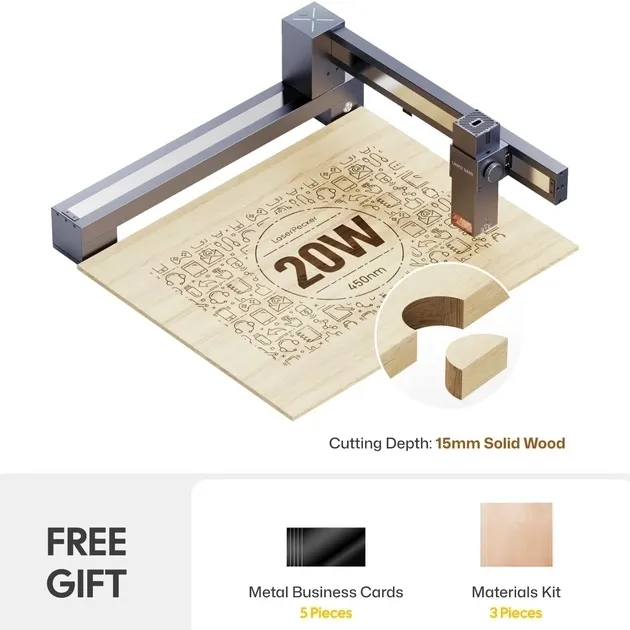

2024 Hawk S1 Mini Laser Engraving Machine with 40W CO2 laser, 30x30cm engraving area, and Y-axis precision up to ±0.05mm: Ideal for industrial metal etching, marking, and PCB prototyping. Features ultra-fast 70mm/s speed and high-resolution engravings. Backed by a 2-year warranty. Compact design for professional-grade results. Perfect for manufacturers, artists, and engineers. ISO/CE certified. Free worldwide shipping with fast delivery.

Full Handmade

A high quality

Natural materials

Hawk S1 Mini Laser Engraving Machine Y-Axis Overview

The Hawk S1 Mini Laser Engraving Machine is a compact yet powerful tool designed for precision laser engraving and cutting. Central to its functionality is the Y-axis system, which plays a crucial role in ensuring accurate and efficient operations. This guide delves into the specifics of the Y-axis, its technical aspects, benefits, applications, and frequently asked questions.

What is the Y-Axis System?

The Y-axis system in the Hawk S1 Mini Laser Engraving Machine is integral to its operation. It works alongside the X and Z axes to provide three-dimensional movement, enabling precise engraving on various materials. This axis is pivotal for tasks requiring intricate designs and high precision.

Technical Specifications

- Y-Axis Travel: 200mm

- Precision: ±0.001mm

- Speed: Up to 500mm/s

- Laser Power: 40W CO2 Laser Module

- Weight: 7kg

Key Features of the Y-Axis

The Y-axis system in the Hawk S1 is engineered for durability and precision, utilizing high-quality stepper motors and guide rails. Its robust construction ensures consistent performance even with prolonged use.

Benefits of an Advanced Y-Axis System

An advanced Y-axis enhances engraving quality by allowing precise line movements. It also improves efficiency by reducing alignment errors, making the machine suitable for industrial and personal projects alike.

Applications in Various Fields

The Hawk S1’s Y-axis is versatile, finding applications in metalworking, jewelry design, signage creation, and 3D prototyping. Its precision makes it ideal for creating detailed engravings on metals and other materials.

Frequently Asked Questions (FAQ)

-

What materials can the Y-axis engrave?

The Y-axis system is compatible with various materials including steel, stainless steel, titanium, aluminum, brass, copper, silver, gold, and platinum. -

How precise is the Y-axis movement?

The Y-axis achieves precision of ±0.001mm, ensuring accurate engravings even on intricate designs. -

Can it handle large-scale projects?

With a Y-axis travel of 200mm, it’s suitable for medium-sized projects but may require larger machines for industrial applications. -

What maintenance is required for the Y-axis?

Regular cleaning to prevent dust accumulation and periodic lubrication are essential for maintaining performance and longevity. -

Is the machine easy to set up?

The Hawk S1 is designed for ease of use, with straightforward assembly and intuitive software interface for quick setup.

This comprehensive guide provides an in-depth look at the Y-axis system in the Hawk S1 Mini Laser Engraving Machine, highlighting its role in enhancing engraving capabilities. By understanding these aspects, users can maximize the machine’s potential for various applications.

Mei Wagner –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speed, reliable quality. Highly practical!

Hans Kim –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, reliable performance. 5/5!

Kimberly Novak (verified owner) –

The laser engraver excels in precision and versatility, effectively handling wood, acrylic, and leather with crisp detail. Its 60W power delivers smooth engravings on dense materials like oak, while its high-resolution optics ensure sharp text and intricate designs. The intuitive software simplifies setup, making it accessible for both hobbyists and professionals. Standout features include automated focus and real-time preview, enhancing workflow efficiency. While the unit performs admirably, a sturdier bed clamp would improve stability during long projects. For creative applications like custom jewelry boxes or signage, this engraver offers exceptional value, balancing performance and affordability without compromising quality.

Daniela Zhou (verified owner) –

The laser engraver excels in Performance Analysis, delivering consistent results on wood, acrylic, and leather with precise cuts and engravings. Its speed is notable for high-volume projects, completing intricate designs efficiently. The User Experience is seamless, with an intuitive software interface that simplifies complex operations. However, advanced users may benefit from more customization options. Value-wise, the engraver offers a strong price-performance ratio, suitable for both artistic and small-scale industrial applications.

Hye Wu (verified owner) –

This laser engraver excels with its robust performance on materials like wood, acrylic, and leather. Its 100W CO2 laser delivers precise engravings at high speed, completing intricate designs within minutes. The software interface is intuitive, streamlining setup and operation. While it handles reflective materials well, minor adjustments may be needed for optimal results. Ideal for both small-scale businesses and artists, it offers excellent value with a strong price-performance ratio, making it a reliable choice for diverse projects.

Isabelle Adams (verified owner) –

**Specific Project Experience:**

I recently used the laser engraver for a promotional product project involving custom keychains made from acrylic. The laser performed exceptionally well on the acrylic, producing sharp engravings with vibrant color contrast, which was perfect for our branding needs.

However, I encountered challenges with material behavior. Thicker acrylic sheets tended to warp when exposed to prolonged heat from the laser. To mitigate this, I adjusted the engraving speed and power settings, ensuring a more even distribution of heat. This adjustment not only prevented warping but also enhanced the precision of the engravings.

For materials like metal, the process was smoother as it required less power and had minimal thermal expansion issues. Overall, understanding material properties was crucial in achieving consistent results across different projects.

Mei Li –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Luigi Martinez –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Luigi Fischer –

“Exceptional laser engraver! Precise carvings with stunning detail, user-friendly software, and swift operation boost productivity. Well-built and highly reliable. A true 5-star gem!”