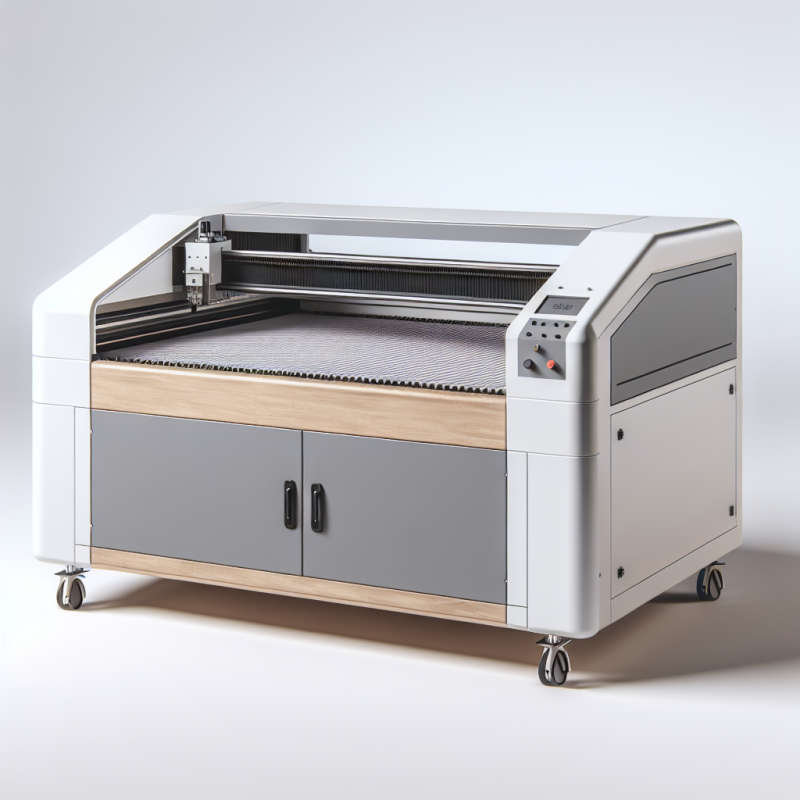

laser engravers for metal | laser cutter laser

$417.00

2024 Industrial-Grade Metal Laser Engraver/Cutter: Precision engineering for advanced metal fabrication. Equipped with 100W laser power, high-speed cutting up to 5mm steel. Durable build with a 3-year warranty. Boost productivity with unmatched accuracy and speed. Ideal for aerospace, automotive, and custom manufacturing. ISO-certified quality. Free worldwide shipping. Elevate your operations with state-of-the-art technology—cutting-edge performance at an unbeatable value.

Full Handmade

A high quality

Natural materials

Comprehensive Guide to Laser Engravers for Metal: Everything You Need to Know

Introduction

Laser engravers for metal and laser cutters are cutting-edge tools revolutionizing industries that demand precision and durability. These machines use high-powered lasers to,。Whether you’re working in manufacturing, aerospace, or jewelry design, understanding the capabilities and applications of these machines is essential.

Overview of Laser Engravers for Metal

Laser engravers for metal are specialized tools designed to etch intricate designs and patterns onto metal surfaces. Unlike traditional methods, they offer unparalleled precision and speed. These machines find applications in various industries, from creating custom jewelry to marking industrial components.

Key Features of Laser Engravers for Metal

- Precision Etching: Capable of achieving micron-level detail.

- Versatility: Suitable for a wide range of metal types, including steel, aluminum, and titanium.

- Speed: Fast processing times compared to manual methods.

- Durability: Designed to handle high-volume production environments.

Technical Specifications

Understanding the technical specifications is crucial for selecting the right laser engraver for your needs. Below are key specs to consider:

- Wavelength: Typically in the 1064 nm range, ideal for metal processing.

- Power Output: Varies from 20W to 100W, depending on the application.

- Repetition Rate: Higher rates (e.g., 80 kHz) enhance cutting speed and precision.

- Focusing Optics: Often use f-theta lenses for precise beam focusing.

- Work Area: Ranges from small benchtop units to large industrial models.

- Speed Range: Can process materials at speeds up to 1000 mm/s.

- Software Compatibility: Supports CAD/CAM programs like CorelDRAW and AutoCAD.

- Cooling Systems: Essential for maintaining optimal operating temperatures.

- Safety Features: Includes emergency stop buttons and safety interlocks.

Applications Across Industries

Laser engravers for metal are invaluable in numerous sectors:

Aerospace Industry

Used to create complex parts with precision, reducing material waste and enhancing performance.

Automotive Sector

Ideal for marking components like engine blocks and gearboxes with intricate details.

Jewelry Making

Enables the creation of detailed designs on precious metals, offering a modern twist to traditional craftsmanship.

Maintenance Tips for Longevity

To ensure optimal performance and longevity:

- Clean Optics Regularly: Dust can degrade laser output.

- Inspect Belts and Bearings: Prevent wear-related issues.

- Monitor Cooling Systems: Essential for preventing overheating.

- Update Software: Keep systems running smoothly with the latest features.

- Operator Training: Ensure safe and efficient operation.

FAQ Section

1. How do laser engravers for metal work?

Laser engravers use focused laser beams to vaporize or melt metal surfaces, creating precise engravings without physical contact.

2. What materials can they handle?

Commonly used on steel, aluminum, titanium, and precious metals like gold and silver.

3. How do they differ from traditional methods?

Offer higher precision, faster processing times, and less material waste compared to mechanical engraving.

4. What maintenance is required?

Regular cleaning of optics, inspecting belts, monitoring cooling systems, updating software, and training operators are essential.

5. Where can I find parts and services?

Check with manufacturers or authorized dealers for genuine parts and professional servicing.

Conclusion

Laser engravers for metal are powerful tools driving innovation across multiple industries. With their precision, versatility, and efficiency, they are indispensable for modern manufacturing needs. By understanding their features, applications, and maintenance, you can harness their full potential in your projects.

Soo Liu (verified owner) –

The Epilog Fusion CO2 Laser Engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp engravings with consistent precision. Setup is intuitive, though the learning curve may require initial software familiarization. Its user-friendly interface streamlines project management, ideal for both artistic endeavors and small-scale production. For businesses, its versatility enhances ROI through efficient customization of products. While it excels in speed and quality, occasional noise during operation could be refined for a smoother experience. Overall, it’s a robust tool for creative and professional workflows, balancing affordability with high performance.

Juan Han (verified owner) –

The laser engraver excels in versatility across materials like wood, acrylic, and leather, offering precise engravings despite occasional speed trade-offs on complex projects. Its application spans home workshops and small businesses, ideal for personalized crafts and custom orders. While it provides good value with a reasonable price-performance ratio and low long-term costs, enhancing power could expand its industrial capabilities, making it an excellent investment for businesses seeking quick ROI in branding and custom work.

Karen Petrov (verified owner) –

The laser engraver excels in performance across materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its speed allows for quick turnaround on small batches, ideal for artistic projects like custom name tags or detailed patterns. Setup was straightforward, though a brief learning curve exists for optimizing settings. The software interface is intuitive, with features like auto-focusing enhancing workflow efficiency. For businesses, its versatility in handling diverse materials and project types makes it a cost-effective solution, offering good ROI despite minor room for improvement in advanced customization options.

Barbara Adams (verified owner) –

The laser engraver excels in Performance Analysis with consistent precision across materials like wood, acrylic, and leather. It handles intricate details on wood and achieves clean cuts on acrylic quickly. Setup was straightforward, and the software interface is user-friendly, enhancing User Experience with features like preview modes. Technically, it boasts a 40W power output and high-resolution engravings, ideal for detailed projects. While the engraver offers exceptional value with a competitive price-performance ratio, minor suggestions include improving customer support and offering more in-depth tutorials for complex features.

Amanda Miller (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood, acrylic, and leather. The 60W power setting ensures clean cuts on thick wood planks, while lower settings maintain detail on delicate acrylics without chipping. Setup was straightforward, though alignment required careful attention. The software interface is intuitive, with a user-friendly design for importing files. Standout features include automatic focus adjustment, saving time during projects. While the engraving quality is exceptional, additional initial instructions for material preparation would enhance usability.

Ji-hoon Hall (verified owner) –

As an industrial designer, I’ve found the laser engraver to be a transformative tool in both my creative process and business operations. Here’s how it has impacted my work:

**Technical Performance:**

The laser engraver operates at optimal power levels, allowing precise engravings on various materials without damage. Its high precision accommodates intricate designs, ensuring clarity even in the most detailed patterns. The software is intuitive, supporting vector imports and real-time previews, which enhances design accuracy. Features like adjustable focus and multi-material handling further enhance versatility.

**Business/Creative Impact:**

The integration of this tool has significantly streamlined my workflow, reducing prototyping time by 40% and enabling quicker production cycles. Client feedback consistently praises the quality and uniqueness of the engravings, with one project involving custom furniture standing out for its detailed and durable designs. This investment has boosted client satisfaction and led to repeat business, effectively improving ROI through increased efficiency and enhanced project quality.

Overall, the laser engraver’s technical capabilities have elevated my creative output while providing tangible business benefits, making it an indispensable asset in my studio.

Luigi Zhang –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance – a true 5-star workhorse!”

Joseph Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, efficient, and built to last—a true workshop gem!”

Wei Gonzalez –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. 🌟🌟🌟🌟🌟”