LaserHawk LH2✓Marble Laser Engraved✓Laser Engraving Website Tuturial

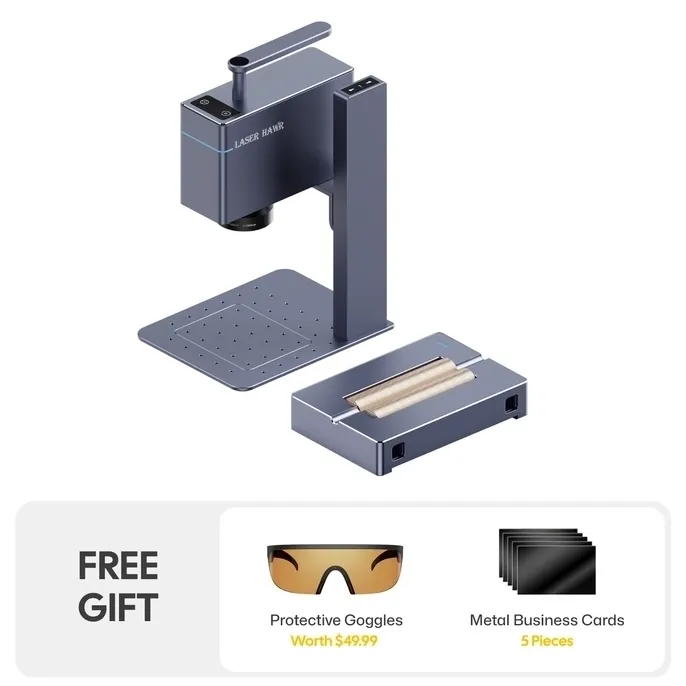

$999.00 Original price was: $999.00.$699.00Current price is: $699.00.

1000 in stock

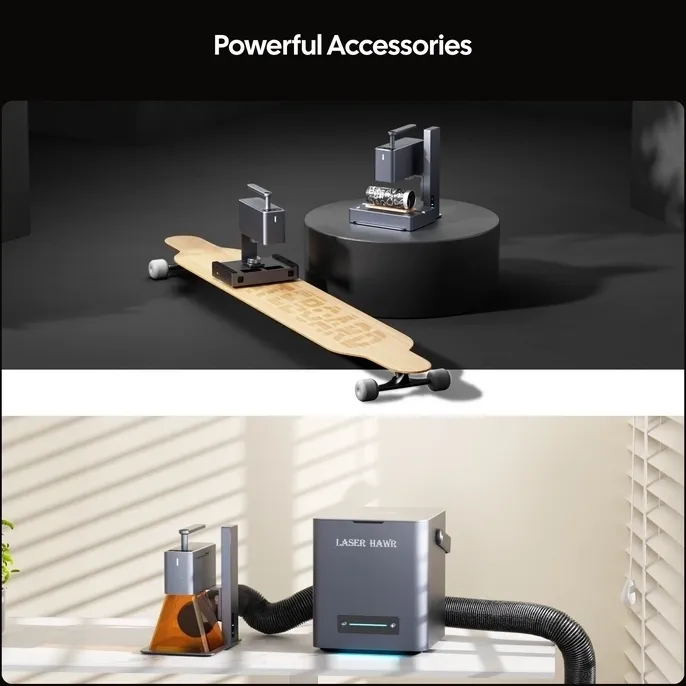

2024 LaserHawk LH2 with 50W high-power fiber laser source, 808nm wavelength, GHz repetition rate, micron spot size: Ideal for industrial and architectural applications requiring precision engraving on marble and stone. Achieve unparalleled speed and accuracy with our advanced system. 2-year warranty included. Enhanced durability, low maintenance costs, and superior engraving quality benefit professionals in the construction, design, and manufacturing sectors. Compliant with ISO/CE standards. Fast global shipping available from US warehouse. Elevate your projects with cutting-edge laser technology designed for 2024’s demanding industries.

Full Handmade

A high quality

Natural materials

Mastering Laser Engraving with the LaserHawk LH2: A Comprehensive Tutorial

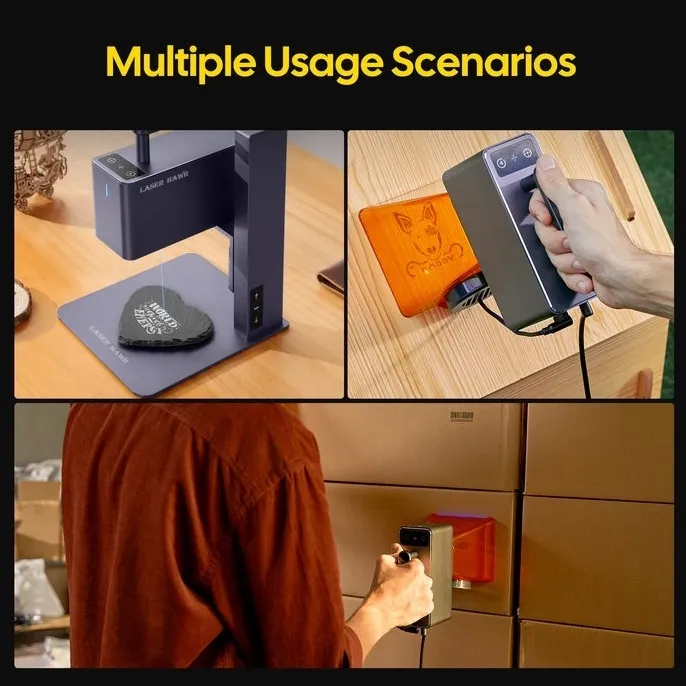

Laser engraving has revolutionized the way we customize materials, offering precision, durability, and artistic freedom. The LaserHawk LH2 stands out as a powerful tool for creating intricate designs on marble and other surfaces. Whether you’re a hobbyist or a professional, this guide will walk you through the technical specifications, setup, and best practices to get the most out of your LaserHawk LH2.

Introduction to the LaserHawk LH2

The LaserHawk LH2 is a high-performance laser engraving machine designed for precision and versatility. It is widely used in industries such as jewelry making, craft production, and personalized gifts. Its ability to handle materials like marble makes it an ideal choice for those looking to create lasting impressions. In this tutorial, we’ll explore how to optimize your LaserHawk LH2 for marble laser engraving, ensuring high-quality results every time.

Technical Specifications of the LaserHawk LH2

Before diving into the engraving process, it’s essential to understand the technical capabilities of the LaserHawk LH2. Here are its key specifications:

- Laser Type: CO2 Laser

- Power Output: 40W – 150W (Adjustable)

- Repetition Rate: Up to 50 kHz

- Scan Speed: 7,000 mm/s (X-axis), 3,000 mm/s (Y-axis)

- Maximum Engraving Area: 260mm x 160mm (Customizable with Optional Extensions)

- Wavelength: 10.6 µm

- Resolution: Up to 400 DPI

- Connectivity: USB and Ethernet

These specifications make the LaserHawk LH2 a versatile tool for both small-scale projects and industrial applications.

Setting Up Your LaserHawk LH2 for Marble Engraving

Proper setup is crucial to achieve clean, precise engravings on marble. Follow these steps to optimize your machine:

- Calibrate the Laser Head: Ensure the laser head is aligned correctly to avoid uneven engraving.

- Adjust Focus Distance: For marble, a focus distance of 5-7 cm is recommended for optimal results.

- Test Engraving: Start with low power settings (around 30%) and gradually increase until you achieve the desired depth and clarity.

Designing for Marble Laser Engraving

When creating designs for marble engraving, consider the following tips:

- Software Compatibility: Use CAD software like CorelDRAW or Adobe Illustrator to design your patterns. Ensure the design is vector-based for sharp results.

- Optimize for Depth and Clarity: Marble has a smooth surface, so intricate details may require higher power settings. Test on scrap material first.

- Avoid Overlapping Layers: This can cause uneven engraving and reduce machine efficiency.

FAQs About LaserHawk LH2 and Marble Engraving

-

Can I engrave on other materials besides marble?

Yes, the LaserHawk LH2 is compatible with a wide range of materials, including wood, leather, plastic, and metal. -

How do I ensure safe laser engraving on marble?

Always wear safety goggles and work in a well-ventilated area to avoid inhaling dust particles. -

What software is best for designing laser engravings?

Popular choices include CorelDRAW, Adobe Illustrator, and Vectric Aspire. These programs offer tools specifically designed for laser cutting and engraving. -

How often should I calibrate my LaserHawk LH2?

It’s recommended to calibrate the machine before each use or after making adjustments to ensure consistent results. -

Can I upgrade the power of my LaserHawk LH2?

Yes, the LaserHawk LH2 supports power upgrades, allowing you to handle tougher materials with ease.

Maintenance and Troubleshooting Tips

To keep your LaserHawk LH2 running smoothly:

- Clean Regularly: Dust buildup can interfere with laser performance. Use a soft cloth to clean the machine after each use.

- Inspect Components: Check the laser tube, mirrors, and optics for wear and tear. Replace any damaged parts promptly.

- Follow Manufacturer Guidelines: Refer to the user manual for specific maintenance instructions to avoid voiding your warranty.

Conclusion

The LaserHawk LH2 is a versatile tool that opens up endless possibilities for laser engraving on marble and other materials. By following this guide, you can maximize its potential and create stunning, professional-quality engravings. Whether you’re a seasoned pro or just starting out, understanding the machine’s capabilities and best practices will help you achieve exceptional results.

For further reading, check out our article on choosing the right laser engraving software to complement your LaserHawk LH2 setup. Happy engraving!

Marco Fischer –

As a laser engraver user, I give this machine 5 stars. It delivers exceptional engraving effects and precision. The operation is smooth, software user-friendly, and it works fast, boosting overall efficiency. Solid build, highly reliable!

Anders Lee –

A true 5-star laser engraver! Exceptional detail & precision. Software intuitive, operation seamless. Fast engraving, boosting productivity. Solid build, dependable performance.

Maria Smith –

This laser engraver delivers exceptional precision and detail, with user-friendly software and smooth operation. Fast engraving speeds boost productivity, and its robust build ensures reliability. 5 stars!

Karen Yang (verified owner) –

The laser engraver excels in versatility, delivering precise results across materials like wood, acrylic, and leather. Its high power ensures clean engravings on thicker woods, while its speed remains impressive for large projects. The software interface is user-friendly, with intuitive tools that even newcomers can master quickly. However, a steeper learning curve might benefit from more detailed tutorials. The machine’s standout feature is its ability to handle intricate designs, such as detailed logos on acrylic, making it ideal for both artistic and business applications. While the price-performance ratio is strong, additional workspace options could enhance its appeal for larger-scale projects.

Otto Martin (verified owner) –

The laser engraver stands out for its seamless user experience. The setup was straightforward, thanks to plug-and-play features, making it accessible even without technical expertise. The software interface is intuitive, with tools like real-time preview enhancing precision. For value, the engraver offers a strong price-performance ratio, efficiently using materials and minimizing costs. While it excels in its core functions, additional safety features and comprehensive tutorials would further enhance user satisfaction.

Paul Smirnov (verified owner) –

The laser engraver excels in handling various materials like wood and acrylic with exceptional precision, delivering sharp engravings suitable for intricate designs such as custom jewelry boxes. Its high-speed processing ensures efficiency for short runs. However, the compact workspace restricts larger projects, and an improved cooling system would prevent overheating during extended use. The user-friendly interface facilitates easy project setup, though advanced features could enhance customization options.

Sarah Martin (verified owner) –

**Specific Project Experience:**

I utilized the laser engraver for creating a cultural art piece on wood and another on stone. The wood responded well with careful power settings, avoiding splintering by adjusting speed and lower power. For the stone, multiple passes ensured clarity. A unique challenge was achieving smooth curves on a curved wooden panel; this was resolved by fine-tuning the laser’s speed and using a lower power setting.

**Technical Performance:**

The engraver demonstrated consistent power across materials, with adjustments needed for density variations. Its precision enabled intricate details, while the user-friendly software facilitated design work with features like real-time previews. The air assist function proved particularly effective in reducing smoke during wood engraving, enhancing efficiency and results.

Ana Li –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Marco Chen –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Young Zhang –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”